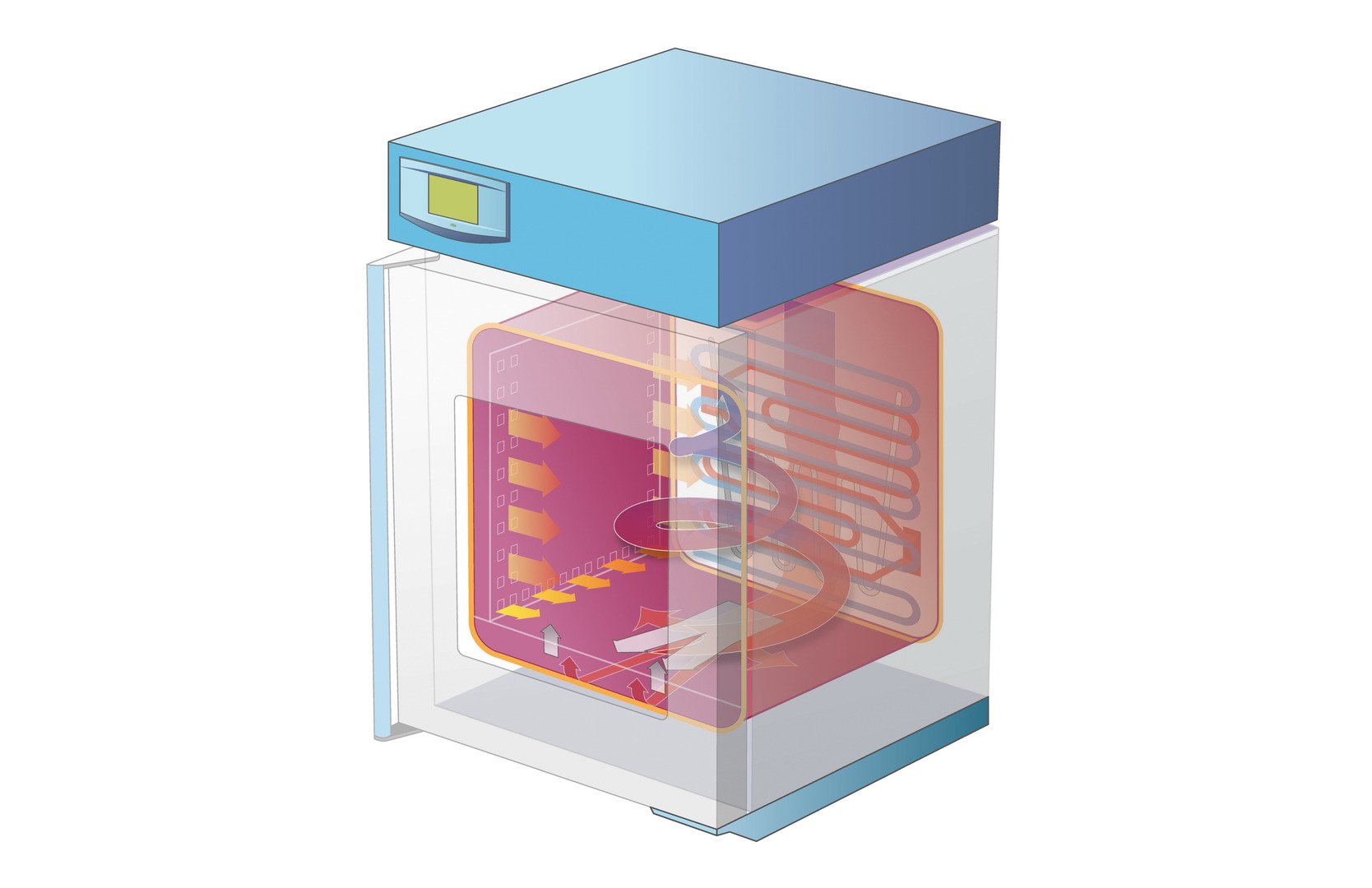

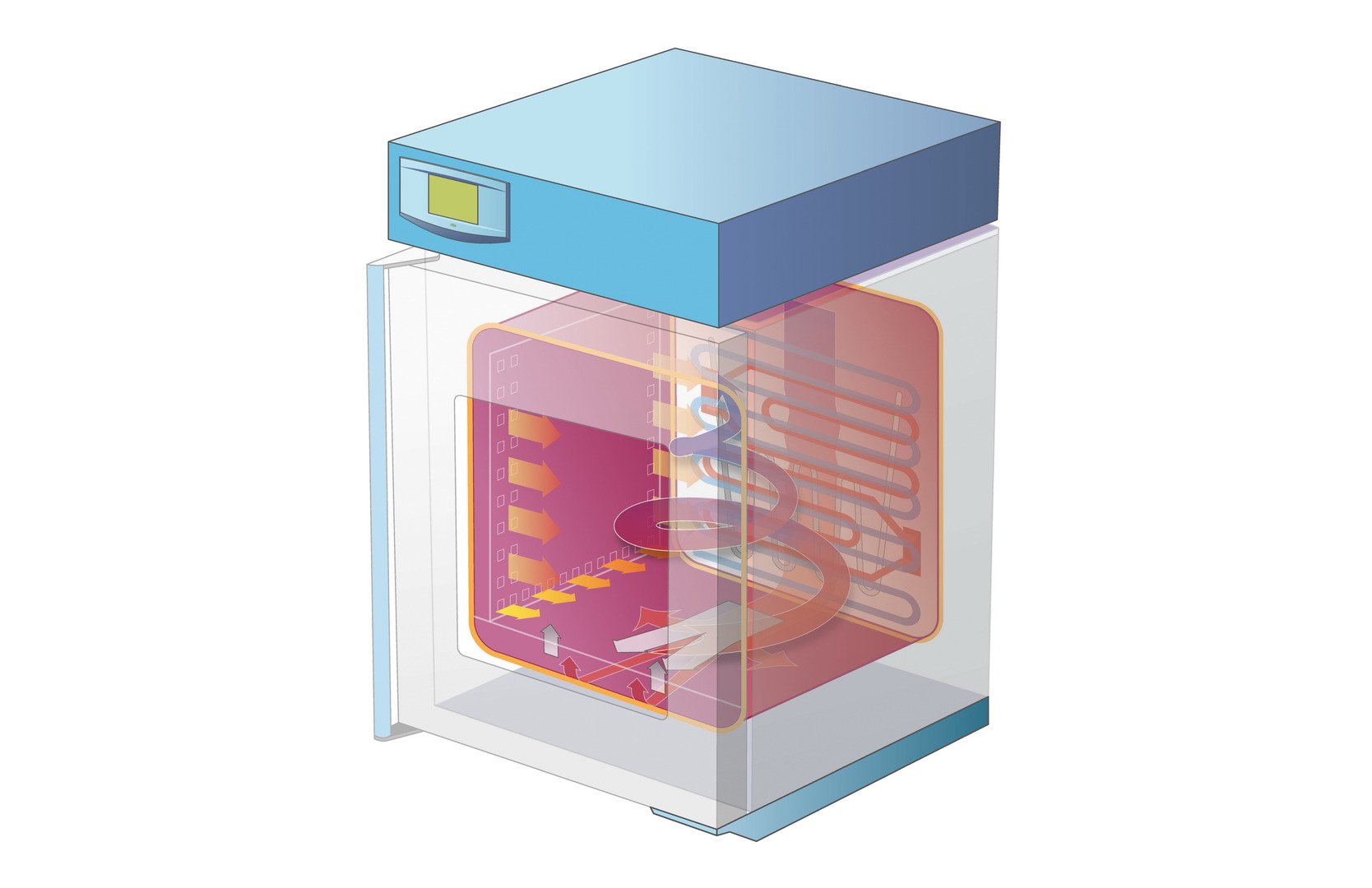

The principle of operation is based on fine forced circulation of air in connection with patent-protected powerful cooling and humidifier located in the chamber. The multi-processor control system of active humidification and dehumidification with powerful lighting system guarantees excellent homogenous conditions for exact simulation of selected climatic actions.

New generation of the CLIMACELL® device offers wide possibilities of selected lighting use. The variability of placement, selection of light sources, user friendliness and possibility of fluent intensity control meet even the most demanding requirements towards applications with exposure lighting.

- Fluorescent tubes in doors

- Fluorescent Tubes in shelves

- LED lighting in the door

- White LED lighting in shelves

The device CLIMACELL® is designed for applications requiring exact and reproducible simulation of variable climatic conditions. The basic version of the incubator allows simultaneous regulation of temperature and humidity. In case of optional equipment buying, the device offers regulation of CO2 respectively other gases concentration or space-homogenous lighting in the field of visible or UV light with adjustable intensity and possibility of intensity measuring using special probes. Thanks to the unique combination, the device offers a wide range of possible applications to users. CLIMACELL® can be used in biology, food processing, chemical industry, electrical technology, histology, botany, pharmacy and in other branches. As a typical example it is possible to state cultivation of plant and tissue cultures or stability (photo-stability) tests of materials and medicaments. Simple control via touch screen, exact regulation and many possibilities of data outputs meet the most demanding conditions of pharmaceutical industry and they also allow user-friendly simulation of simple requirements towards plants growing. Microprocessor-controlled system of humidification and dehumidification together with high-performance programmable system of exposition lighting guarantees excellent homogenous parameters for tests and growth conditions.

Meeting the requirements of regulations 2014/35/EU, 2014/30/EU, ICH 279/95 Option 2, FDA 21 Part 11, 2011/65/EU, 517/2014/EU.

Sturdy design and perfect protection against corrosion are ensured by a self-supporting outer jacket made of galvanized steel sheet with hard and resistant baking varnish on the outer side. The inner double-jacket chamber and the door panel are made of high-quality stainless steel (DIN 1.4301, AISI 304). For the purposes of energy saving and minimizing the heat radiated to the ambient air, the chamber is perfectly insulated with an ecological insulating material. The inner walls of the chamber can be easily removed without using any tool, e.g. for the purposes of cleaning. On top of that the chamber has a fan with a speed regulation, and an inner glass door. The door is secured at four points for perfect tightening.

Changes in the design and make reserved.

CLIMACELL 111 - ECO line

CLIMACELL 111 - ECO line  CLIMACELL 222 - ECO line

CLIMACELL 222 - ECO line  CLIMACELL 404 - ECO line

CLIMACELL 404 - ECO line  CLIMACELL 707 - ECO line

CLIMACELL 707 - ECO line  CLIMACELL 111 - EVO line

CLIMACELL 111 - EVO line  CLIMACELL 222 - EVO line

CLIMACELL 222 - EVO line  CLIMACELL 404 - EVO line

CLIMACELL 404 - EVO line  CLIMACELL 707 - EVO line

CLIMACELL 707 - EVO line